sheena's dad said:Jack,

Soon as I can, I'll get a drawing put together for the jigs, if you'd like to see them. The one I've got built now does wonders with a router on a table. The other I'm still working out but looks like I'll have the same success with it. That is if you're interested.

If you don't mind, I'd be real interested in seeing some plans for that.

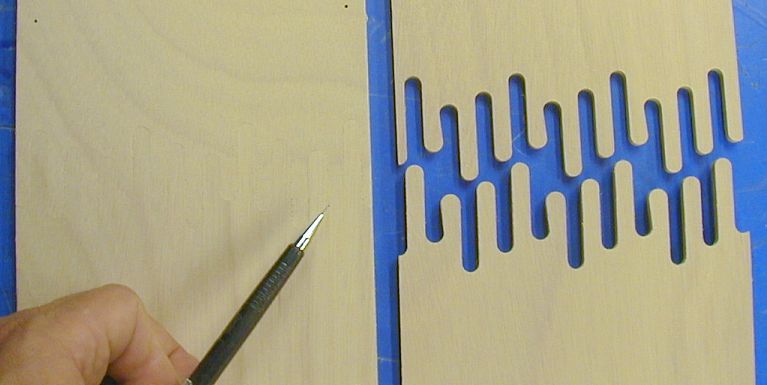

In case anyone is interested, here's a set of plans for scarfing with a circular saw.

http://www.oneoceankayaks.com/stitchglue/plyshophtm/scarfjig2.htm

Clint