A sign of things to come...

- Thread starter rpecot

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trust me, I'm not that good!

The day started out right when I found this in my mailbox:

I'm using ash for the shaft. I had milled one large board into two halves that I will hollow out to save a little on weight, then glue together. Luckily for me, I was able to get three halves out of that board because the first one didn't come out so good. As I said earlier, I'm a little rusty and it showed.

As I said earlier, I'm a little rusty and it showed.

I marked out the area I wanted to hollow and set up my router. First one when well:

Then I started on the second half...

It didn't get any better after that:

When the router bit, it must have nudged my fence. I didn't think to re-check it. Having that hollowed out section off center will make the wall thickness too thin (if not non-existent).

Having that hollowed out section off center will make the wall thickness too thin (if not non-existent).

Needless to say I was a little peeved. After an hour bike ride through the neighborhood, I've calmed down a little. Guess I will be heading back to Houston Hardwoods before I can finish this job.

The day started out right when I found this in my mailbox:

I'm using ash for the shaft. I had milled one large board into two halves that I will hollow out to save a little on weight, then glue together. Luckily for me, I was able to get three halves out of that board because the first one didn't come out so good.

I marked out the area I wanted to hollow and set up my router. First one when well:

Then I started on the second half...

It didn't get any better after that:

When the router bit, it must have nudged my fence. I didn't think to re-check it.

Needless to say I was a little peeved. After an hour bike ride through the neighborhood, I've calmed down a little. Guess I will be heading back to Houston Hardwoods before I can finish this job.

Russ,

If you have a table saw you could make a birds mouth shaft. Come to think about it I think Ron did one here while back. There is a formula you can use to size the strips with. You can even make a tapered shaft for a sail mast or whatever. I will try to find that. It's squrrelled away somewhere.

Bob

If you have a table saw you could make a birds mouth shaft. Come to think about it I think Ron did one here while back. There is a formula you can use to size the strips with. You can even make a tapered shaft for a sail mast or whatever. I will try to find that. It's squrrelled away somewhere.

Bob

Ron,

Thanks for that. I have not seen those before. The formula I had from years back you have to work out with impliments fron the past, pencil and paper. I like yours better. Thanks.

Bob

Thanks for that. I have not seen those before. The formula I had from years back you have to work out with impliments fron the past, pencil and paper. I like yours better. Thanks.

Bob

Thats the calculator I use to, have now made a number of birdsmouth items from paddle shafts to 25' main mast. 1st attempt was somewhatt frustrating, but with practice it's become almost fun (sadistic).

MM[url

][/url]

][/url]

MM[url

Baby steps...

I went' back to the lumber yard and got two pieces of milled ash, 3/4"x1-1/2"x10'. In the aftermath of my earlier screw-up, I recalled that I had built a router mortise jig for a "future" project. It would be perfect for this application. So, consciously trying NOT to rush myself, I laid out my lines on the new boards and prepped for the router. It went very well today.

Not a great pic of the jig:

And the result:

The plan is to trim down about 1/8" on either side of the wall thickness you see there. The paddle shaft will be about 1-1/4" diameter. I left 20" at each end un-routed for the paddle faces, as well as about 2" - 4" (depending on the final length) in the middle for when I attach the paddle ferrule.

Here are the two halves, glued up:

I went' back to the lumber yard and got two pieces of milled ash, 3/4"x1-1/2"x10'. In the aftermath of my earlier screw-up, I recalled that I had built a router mortise jig for a "future" project. It would be perfect for this application. So, consciously trying NOT to rush myself, I laid out my lines on the new boards and prepped for the router. It went very well today.

Not a great pic of the jig:

And the result:

The plan is to trim down about 1/8" on either side of the wall thickness you see there. The paddle shaft will be about 1-1/4" diameter. I left 20" at each end un-routed for the paddle faces, as well as about 2" - 4" (depending on the final length) in the middle for when I attach the paddle ferrule.

Here are the two halves, glued up:

Russ, if this is to be a kayak paddle, consider not making the shaft round. A slightly egg shaped shaft feels a lot better in the hands, and is self-centering for blade angle in practical use. Aim the egg shape to lie "flat" in your hands. The long axis of the egg lies at a 90 degree angle to the vertical of the blades.

Trying this again. After typing up an update, my 6 yo came over and closed my browser window before I could hit submit. :evil:

Anyway... slow progress. I glued up the paddle face laminations. That's maple, cherry, mahogany, and cherry again. Second pic is with mineral spirits.

After you've glued up the material and it's setting in clamps is not the ideal time to start thinking about how you are going to cut up the wood. I don't have a bandsaw. The block of wood is about 4" thick. Problem. After thinking about it a while, I realized I have three things I could utilize to get the job done. 1. A pull saw. 2. A sanding station. 3. Time.

Here's the block, with the paddle face profiles marked up and some progress with the pull saw.

One piece cut and sanded.

Two pieces sanded and placed along side the paddle shaft.

Anyway... slow progress. I glued up the paddle face laminations. That's maple, cherry, mahogany, and cherry again. Second pic is with mineral spirits.

After you've glued up the material and it's setting in clamps is not the ideal time to start thinking about how you are going to cut up the wood. I don't have a bandsaw. The block of wood is about 4" thick. Problem. After thinking about it a while, I realized I have three things I could utilize to get the job done. 1. A pull saw. 2. A sanding station. 3. Time.

Here's the block, with the paddle face profiles marked up and some progress with the pull saw.

One piece cut and sanded.

Two pieces sanded and placed along side the paddle shaft.

You are one, determined, fellow. This paddle is going to be a family heirloom for several generations to come.

Re: A sign of things to come... (lots of pics)

Wife + kids + holidays = not much time for Dad's projects.

I have managed to get some work in though. I sawed the hell out of that block of wood and managed to find 4 quarters of paddle blades in there. I earned 'em. That was some work there.

As of this morning, I've glued up both paddle halves.

Yesterday I cleaned up the excess material on paddle#1

I started sawing out the inside, then saw how this was going to be a not-so-fun job.

So I pulled out the spokeshave and started taking out some frustrations on that ash...

That was fun, but yeah, I had to work for that too. Here's the final product (so far)

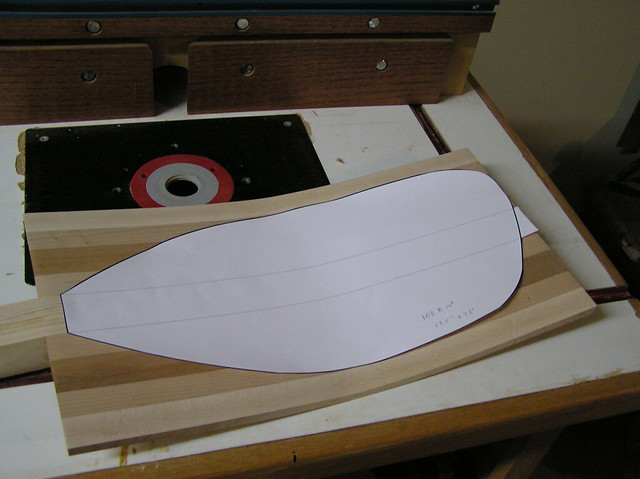

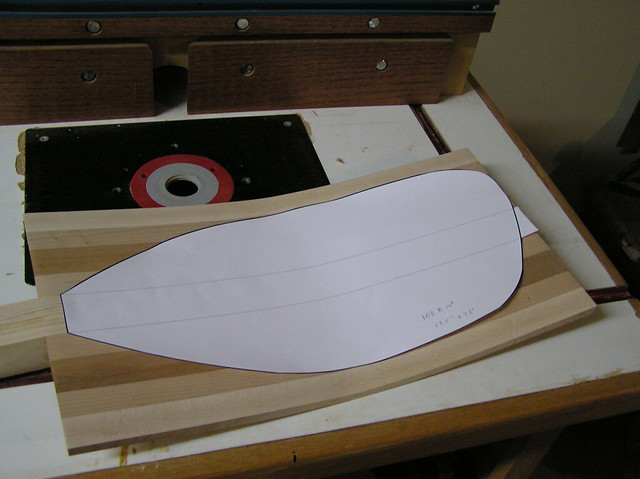

Blade shape. Drawn in Microsoft Visio. 103.8 sq in surface area (approximately ) All but a sliver of maple will get trimmed off. Oh well.

) All but a sliver of maple will get trimmed off. Oh well.

And of course, my little helper. Who, any day now, will be adding "two front teeth" to her wish list.

Wife + kids + holidays = not much time for Dad's projects.

I have managed to get some work in though. I sawed the hell out of that block of wood and managed to find 4 quarters of paddle blades in there. I earned 'em. That was some work there.

As of this morning, I've glued up both paddle halves.

Yesterday I cleaned up the excess material on paddle#1

I started sawing out the inside, then saw how this was going to be a not-so-fun job.

So I pulled out the spokeshave and started taking out some frustrations on that ash...

That was fun, but yeah, I had to work for that too. Here's the final product (so far)

Blade shape. Drawn in Microsoft Visio. 103.8 sq in surface area (approximately

And of course, my little helper. Who, any day now, will be adding "two front teeth" to her wish list.

Looking great, Russ. Right about now, you're realizing why they charge so much for custom wood paddles. :wink:

Joey

Joey

Boy oh boy, Grandpa Russ! Those sure are neato paddles. Will they be ready for Christmas? I'll get a lot longer stocking to hang up to hold'em. WOW!

Haha! Don't you know it! I've spent about $50 on materials (if even that much), but you'd have to offer me an obscene amount of money to part with these right now. :lol:jdupre' said:Looking great, Russ. Right about now, you're realizing why they charge so much for custom wood paddles. :wink:

Joey