Lapstrake ?

- Thread starter beekeeper

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chech out th book 'Building Classic Small Craft' by John Gardner, in the back section is included another book ' More Building Classic Small Craft '. This section ( chapter 6 ) is titled ' Four Canoes '.

You will love this book. John Gardner is considered the upmost authority on this subject.

He explains everything. The only problem will be you will want to build everything.

They usualy used white cedar for planking, the dust from red cedar is considered toxic I understand. But planking in this fasion, the boards will dry out and shrink and split if you don't keep them wet, he explains.

Another book to get is, 'Clinker Plywood Boatbuildin Manual' by Iain Oughred.

His boats are all plywood lapstrak, fiberglass cloth, and epoxy. They don't dry out.

Each plank has to be spilled (tapered) on both end and have an overlap to creat the lapstrak effect, and this is also where they are glued together. Then where they converge at the stem you have to rebate the planks, or let it in so the planks start to run together as if flat as they meet the stem on a single plane.

Have not gotten to do one yet myself. But have played with in a mockup form and it isn't as hard as it sounds, it just takes some time, trial and a comfortably thinking chair.

I went and opened the book to the Rushton Canoe and they used 1/4 inch cedar, but they edge planked it, on other clinkers they have some at 1/4, & 3/8.

Iain Oughred uses stuff like 1/4 inch, or 4mm,5mm,&6mm plywood.

You will love this book. John Gardner is considered the upmost authority on this subject.

He explains everything. The only problem will be you will want to build everything.

They usualy used white cedar for planking, the dust from red cedar is considered toxic I understand. But planking in this fasion, the boards will dry out and shrink and split if you don't keep them wet, he explains.

Another book to get is, 'Clinker Plywood Boatbuildin Manual' by Iain Oughred.

His boats are all plywood lapstrak, fiberglass cloth, and epoxy. They don't dry out.

Each plank has to be spilled (tapered) on both end and have an overlap to creat the lapstrak effect, and this is also where they are glued together. Then where they converge at the stem you have to rebate the planks, or let it in so the planks start to run together as if flat as they meet the stem on a single plane.

Have not gotten to do one yet myself. But have played with in a mockup form and it isn't as hard as it sounds, it just takes some time, trial and a comfortably thinking chair.

I went and opened the book to the Rushton Canoe and they used 1/4 inch cedar, but they edge planked it, on other clinkers they have some at 1/4, & 3/8.

Iain Oughred uses stuff like 1/4 inch, or 4mm,5mm,&6mm plywood.

It is what the Vikings used to construct their longboats. (That was the last boat that conquered England.)

Lapstrake boats serves a lot of different purposes beyond nice looking, IMO. As a rule you can build a boat that weighs less. You can surely paint the boat easier by yourself for the larger ones. But you can also build using solid timber if you are a so called purist and not have the numerous issues that comes with drysailing the boat on weekends. Of course you need to be mindfull that its not an absolute dry hull by any means. But lapstrake boats are rarely gushers either when launching the boats.

Now more to the point, its easy to do and as far as paddling, certain designs that are built using the method are not as stable by any means than the typical harchine pirogue type hulls because of the soft turn of the bilge. But like all small boats, it a matter of getting use to. They will normally respond easier to the paddle. With the lighter weight that in most cases comes with this method, portability by one person is probably what you truely gain with the method for the size boat.

Now more to the point, its easy to do and as far as paddling, certain designs that are built using the method are not as stable by any means than the typical harchine pirogue type hulls because of the soft turn of the bilge. But like all small boats, it a matter of getting use to. They will normally respond easier to the paddle. With the lighter weight that in most cases comes with this method, portability by one person is probably what you truely gain with the method for the size boat.

Oyster

My understanding, 2 kinds of builds:

1. Traditional = solid boards with mechanical fastners

2. Modern = plywod with epoxy and fiberglass

I assume the traditional build is the leaker?, because of the fit between the strakes swelling and opening, correct?

"Strakes" is the correct term for the planks. Yes? or No?

Thanks

beekeeper

My understanding, 2 kinds of builds:

1. Traditional = solid boards with mechanical fastners

2. Modern = plywod with epoxy and fiberglass

I assume the traditional build is the leaker?, because of the fit between the strakes swelling and opening, correct?

"Strakes" is the correct term for the planks. Yes? or No?

Thanks

beekeeper

For some perspective, building lapstrake with solid timber does not create a big leaker these days. Even in the past Simmons built every single boat using lapstrake and not a single bit of filler, sealer of compound in the seams. You could dissasemble them in a flash, but were used in the commercial industry for a couple of decades successfully. They were built with whie cedar early on and then turned to fir plywood and the MDO at the end of his era of building in 1972.

People use flex polyuerthane caulks these days with rviets or even clench nails the old standard for lapstrakes for the small boats. Some of the more thorough builders use a small bead of cotton, which needs some finesse and even can be beaded in larger boats. On occasions flat head machine screws with small nuts has also been used.

With all that said, these days lapstrake boats actually need no fasteners along the laps, only using them at the ends and maybe at some frame locations which carried loads such as thwarts. You also will not be doing any fiberglass work at all, as there is no need for it. YOU can add a lot of weight if you also attempt to do so in small portable hulls too. On small round bilge boats the strakes on the bottom and the turn of the bilge will be some boomerang type shapes. ON occasions we use special made lap clamps for the build until the epoxy cures. Personally I mark the laps when dry fitting and tape the seam inside to save some additional clean up work down the road of the cured epoxy that is pressed out. Clean as you go if at all possible using a small squeeze and pull the tape while the epoxy is green.

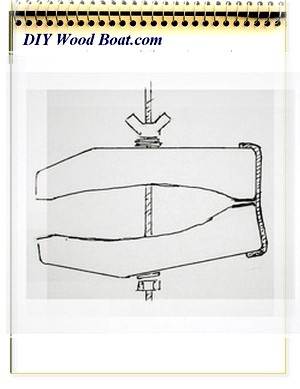

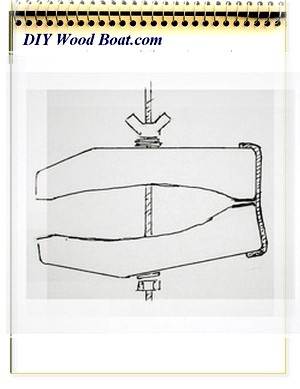

There are several designs for the lap clamps. Many are built using regular plywood. This is just one version.

http://www.diy-wood-boat.com/Clamps.html

People use flex polyuerthane caulks these days with rviets or even clench nails the old standard for lapstrakes for the small boats. Some of the more thorough builders use a small bead of cotton, which needs some finesse and even can be beaded in larger boats. On occasions flat head machine screws with small nuts has also been used.

With all that said, these days lapstrake boats actually need no fasteners along the laps, only using them at the ends and maybe at some frame locations which carried loads such as thwarts. You also will not be doing any fiberglass work at all, as there is no need for it. YOU can add a lot of weight if you also attempt to do so in small portable hulls too. On small round bilge boats the strakes on the bottom and the turn of the bilge will be some boomerang type shapes. ON occasions we use special made lap clamps for the build until the epoxy cures. Personally I mark the laps when dry fitting and tape the seam inside to save some additional clean up work down the road of the cured epoxy that is pressed out. Clean as you go if at all possible using a small squeeze and pull the tape while the epoxy is green.

There are several designs for the lap clamps. Many are built using regular plywood. This is just one version.

http://www.diy-wood-boat.com/Clamps.html

I fail to see how a boat built of, say 4mm plywood, using lapstrake would be lighter or stronger than a similar boat built of the same stuff using S&G construction? For one thing, there is overlap, that means more weight. For another, glassing all those offset joints would be a bloody nightmare. Glass needs a radius of no less that 1/8" or it will separate and leave a bubble all along that edge. Seems to me that moving from a simple S&G to lapstrake is snatching defeat from the jaws of victory.

I like the appearance of lapstrake, but it's been left behind by newer materials and procedures that are simpler, lighter weight, and stronger.

I like the appearance of lapstrake, but it's been left behind by newer materials and procedures that are simpler, lighter weight, and stronger.

The lap creates a structual component using hull scantlings to do so without increasing hull thickness, hince the reason you can reduce your hull scantlings for the entire boat. A S&G depends on a combination of components that creates a seaworthy hull. The additional weight when comparing the two types of construction is in the glass and thickened epoxy fillets along with many interior parts too in some designs. Take a hull that is speced out to be built with 4mm tape and glue and contrast that to simple lapover of the seams, which also actually reduces the need for interior parts too for a sound hull.Kayak Jack said:I fail to see how a boat built of, say 4mm plywood, using lapstrake would be lighter or stronger than a similar boat built of the same stuff using S&G construction? For one thing, there is overlap, that means more weight. For another, glassing all those offset joints would be a bloody nightmare. Glass needs a radius of no less that 1/8" or it will separate and leave a bubble all along that edge. Seems to me that moving from a simple S&G to lapstrake is snatching defeat from the jaws of victory.

I like the appearance of lapstrake, but it's been left behind by newer materials and procedures that are simpler, lighter weight, and stronger.

You're telling me that a hull of identical dimensions will be lighter with lapstrake than S&G??!! (buttoning my pockets here, sewing in my billfold, and sending kids in the house with instructions to lock all doors & windows, and don't let in any strangers). I guess I remain skeptical. Still able to be convinced, but doubtful as all get out.

What I am saying is that a lapstrake hull is structual without a single ounce of fiberglass and one inch or one ounce of thickened epoxy fillet in the boat. The rails and the transfer of stresses fore and aft with a cap and even quarter knees at the transom creates a solid and sea worthy hull, all things being equal in length and beam. Small lapstrake hulls do require some additional work and if you go with an all lapstrake small craft, the shapes are altered by comparison in most cases and for the sake of comparison to pirogues and some of the canoes that incoportate panels and glued seams.Kayak Jack said:You're telling me that a hull of identical dimensions will be lighter with lapstrake than S&G??!! (buttoning my pockets here, sewing in my billfold, and sending kids in the house with instructions to lock all doors & windows, and don't let in any strangers). I guess I remain skeptical. Still able to be convinced, but doubtful as all get out.

length: 11' 6"

beam 27"

weight: 27 lbs.

http://www.thomasjhillboatdesigns.com/charlotte.html

By all means be very skeptical. But a 22' Simmons hull buit using lapstrake construction is built using 9mm and even heavy honduras mahogany framing and finishes off with an open runabout at 1,100 lbs with a 90 hp motor on it, ready to run.

Check out the 18 footer for example, for starters and for the sake of discussion. You cannot recreate this hull in sheet plywood and fiberglass, which is needed for a sound build and come in with less weight .

You can build an 18 and end up with a boat that weighs in at 350 lbs. You can actually push it with a 9.8 Tohastu if you with to, which I have pictures but cannot post them right now.

http://www.simmonsseaskiff.com/SSS%20plans/Infopack.doc

This is a composite fibeglass stringer bottom lapstrake hull sitting on an offical scales. The boat is 24 foot long, 8'2" beam ready to run, fuel included. The trailer weighs 870. The total package sits at 3,000 lbs. The boat required no interal framing even though the main bulkheads does create a structual component for the hull. WHile this is not a Simmons, it shows you what can be done using that building method. I also push the boat with a 40 hp four stroke motor that burns less than four gallons a day, fully loaded and burn about one and a half gallons on a normal fishing trip too.

WOW!!!

That is a pretty boat. When I grow up I want to build boats that look that good.

Jack

Ceck this testimony about the strength/durability:

http://www.thomasjhillboatdesigns.com/a ... veler.html

beekeeper

Another ? Found this statment about lapstrak construction. True? Why?

"It is possible to use wood screws however these should not be used when fastening to steam bent frames."

http://www.diy-wood-boat.com/Lapstrake.html

beekeeper

"It is possible to use wood screws however these should not be used when fastening to steam bent frames."

http://www.diy-wood-boat.com/Lapstrake.html

beekeeper

beekeeper said:Another ? Found this statment about lapstrak construction. True? Why?

"It is possible to use wood screws however these should not be used when fastening to steam bent frames."

http://www.diy-wood-boat.com/Lapstrake.html

beekeeper

Nothing but a guess on my part, but I suspect steam bent frames are subject to more movement with humidity and other moisture changes.

Keith, Seedtick?

Mike

Those overlaps are going to add significantly to the rigidity of the hull. If I recall correctly rigidity is a function of thickness cubed. So those overlapped parts are going to be 2 cubed or 8 times as rigid as the non overlapped sections. Lets say 10 percent of the "planks" consist of overlap. So, that overlapped section is 8 times as rigid but only has 10 percent of the surface area, (8 times 0.1) so it contributes a value of 0.8. The non overlapped section contributes a rigidity of 0.9 (1.0 times 0.9). The total rigidity is 0.8 plus 0.9 or 1.7. So, for a twenty percent increase in weight you've gained a increase of rigidity of 70 percent.

Thats a back of envelope simple calculation that may well be a bunch of baloney. But if you think of the overlapped sections as stringers, I think it is apparent they do add significantly to hull rigidity.

Also, in a lapstrake construction your hull can have curvature in 2 dimensions and the joints do not rely at all on fillets for strength. Both these are positives in terms of hull rigidty and/or lightness in comparison to a pirogue.

I would suggest a lapstrake construction is something between a pirouge and a strip construction in terms of its generally characteristics. I suspect a well engineered lapstrake build could compete with a strip build or pirogue build in the rigidity/strength per weight category. And each build type has different advantages, disadvanges, and ways to do it wrong so it is neither particularly light or strong.

Thats a back of envelope simple calculation that may well be a bunch of baloney. But if you think of the overlapped sections as stringers, I think it is apparent they do add significantly to hull rigidity.

Also, in a lapstrake construction your hull can have curvature in 2 dimensions and the joints do not rely at all on fillets for strength. Both these are positives in terms of hull rigidty and/or lightness in comparison to a pirogue.

I would suggest a lapstrake construction is something between a pirouge and a strip construction in terms of its generally characteristics. I suspect a well engineered lapstrake build could compete with a strip build or pirogue build in the rigidity/strength per weight category. And each build type has different advantages, disadvanges, and ways to do it wrong so it is neither particularly light or strong.

I've always like the lapstrake look. But it takes a lot of TLC if the exterior gets banged around because it's almost impossible to apply any fiberglass to the hull for protection. So wood quality becomes even more critical.

Lets accept your back of he envelope calculations as OK. The fasteners then become the weak point. I'd think that glue-nail construction would be a very good thing. I'd want epoxy soaked well into each of those overlapping joints.

BTW, lapstrake was the method of construction used on Viking boats - the last boats to ever successfully invade England's coast. Can't be too shabby.

BTW, lapstrake was the method of construction used on Viking boats - the last boats to ever successfully invade England's coast. Can't be too shabby.

length: 11' 6"

beam 27"

weight: 27 lbs.

These are the specs for the lapstrake,

Sparkys canoe is a 14 ft by 30 inches wide ,that means it is 2 1/2 ft longer and 3 inches wider and also has some small decks and it weighs 30 lbs.

Makin Mends built a thirteen ft Laker that weighed in the low 20s.

I have to agree with Jack here ,I am plenty skeptical of a lot of the stated claims. Longevity is another thing I would worry about.

Ron

beam 27"

weight: 27 lbs.

These are the specs for the lapstrake,

Sparkys canoe is a 14 ft by 30 inches wide ,that means it is 2 1/2 ft longer and 3 inches wider and also has some small decks and it weighs 30 lbs.

Makin Mends built a thirteen ft Laker that weighed in the low 20s.

I have to agree with Jack here ,I am plenty skeptical of a lot of the stated claims. Longevity is another thing I would worry about.

Ron