So I got started on this boat building sickness from this very site, building an UJ Piroge. I enjoyed building that boat so much, I knew I had caught the bug. I've always wanted a canoe so i could take a girlfriend out, or take a river camping trip with buddies and the likes. I looked and looked, and read and read about building strippers, and I finally made the plunge about a month ago. Got the plans, started wood shopping, and well..............i'm knee deep in it now. Here goes...

My plans came in, and I needed something to make the forms from. I went with (i think) 3/4" MDF, and let me tell you, that stuff is HEAVY. I read about other folks getting copies of the plans made and then cutting out each form, but every said how surprisingly expensive that was. I ventured for a more cost effective method, so i tracked down one of those large white paper flip charts, the kind that you'd put on a stand and use for a presentation or something of the sort. I found one where the paper was pretty transparent, and I went to town tracing each half form. Now that I had my paper versions of each full size half form, I cut them out. I was going to put these straight onto the MDF, but I caught wind of another idea along the way to make templates for all the forms. I found this thin fiber board stuff at Lowes that served my purpose nicely, so all my paper forms were attached to this thin board and then cut from there. I'll have to go back and get a picture of my "templates", as i realize now that I dont have one. Anyway, took these half form templates and traced them onto the MDF

Since all I had was a jig saw, I cut as carefully as I could. Looking back, I wish i had cut a little further outside the lines and then gone back with my palm sander to get nice round forms. We'll see how "bad" my forms actually are once i start stripping. I'm planning to use staples, as I dont mind the look of all the little pin holes and theres the chance of those closing up when i wet out the boat prior to putting down the epoxy anyway. Hopefully, my strips will fit the forms and get stapled down and I wont have too many strips that stand proud of the form.

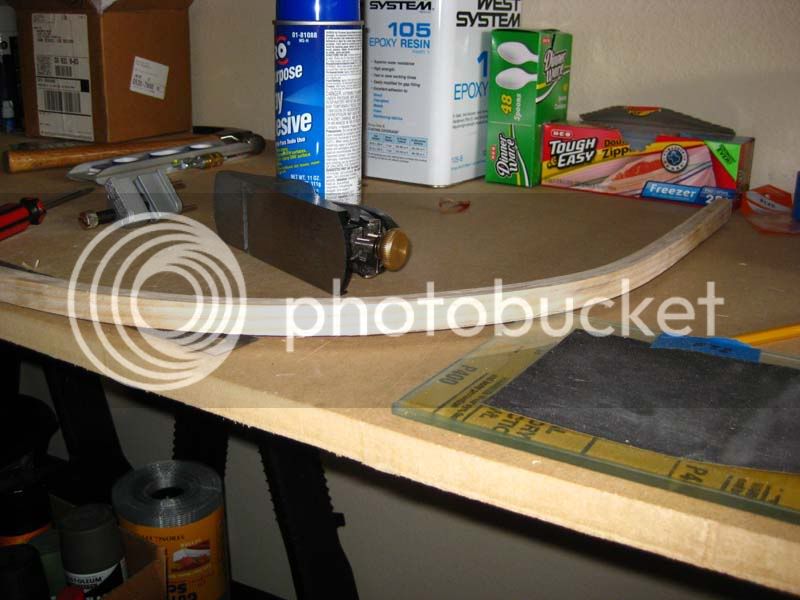

Next step was to get the strongback built. I was going to go with a 2x6 for the top, but when i started fitting it together I didnt like my original idea so i went back to the drawing board. I shifted gears to having a 2x10 on top, with the 2x6 boards hanging from the sides. On the underside I've got some 2x4 boards cut to fit as cross braces.

From there, it was time to mount the forms. Going with the standard single block attached to the form, then attaching that to the strongback, I have to say isnt the most sturdy method. Since this picture I've taken some boards and tried to shore up each form to make them more "move resistant". This was suggested to me from another builder, stating that when you start to sand everything down, you dont want things moving around on ya. Made sense to me! I also went back and made sure all the forms were square and level, which was quite the pain! Detail now though saves the boat later on down the road, so its worth the time to do it right first.

My plans came in, and I needed something to make the forms from. I went with (i think) 3/4" MDF, and let me tell you, that stuff is HEAVY. I read about other folks getting copies of the plans made and then cutting out each form, but every said how surprisingly expensive that was. I ventured for a more cost effective method, so i tracked down one of those large white paper flip charts, the kind that you'd put on a stand and use for a presentation or something of the sort. I found one where the paper was pretty transparent, and I went to town tracing each half form. Now that I had my paper versions of each full size half form, I cut them out. I was going to put these straight onto the MDF, but I caught wind of another idea along the way to make templates for all the forms. I found this thin fiber board stuff at Lowes that served my purpose nicely, so all my paper forms were attached to this thin board and then cut from there. I'll have to go back and get a picture of my "templates", as i realize now that I dont have one. Anyway, took these half form templates and traced them onto the MDF

Since all I had was a jig saw, I cut as carefully as I could. Looking back, I wish i had cut a little further outside the lines and then gone back with my palm sander to get nice round forms. We'll see how "bad" my forms actually are once i start stripping. I'm planning to use staples, as I dont mind the look of all the little pin holes and theres the chance of those closing up when i wet out the boat prior to putting down the epoxy anyway. Hopefully, my strips will fit the forms and get stapled down and I wont have too many strips that stand proud of the form.

Next step was to get the strongback built. I was going to go with a 2x6 for the top, but when i started fitting it together I didnt like my original idea so i went back to the drawing board. I shifted gears to having a 2x10 on top, with the 2x6 boards hanging from the sides. On the underside I've got some 2x4 boards cut to fit as cross braces.

From there, it was time to mount the forms. Going with the standard single block attached to the form, then attaching that to the strongback, I have to say isnt the most sturdy method. Since this picture I've taken some boards and tried to shore up each form to make them more "move resistant". This was suggested to me from another builder, stating that when you start to sand everything down, you dont want things moving around on ya. Made sense to me! I also went back and made sure all the forms were square and level, which was quite the pain! Detail now though saves the boat later on down the road, so its worth the time to do it right first.